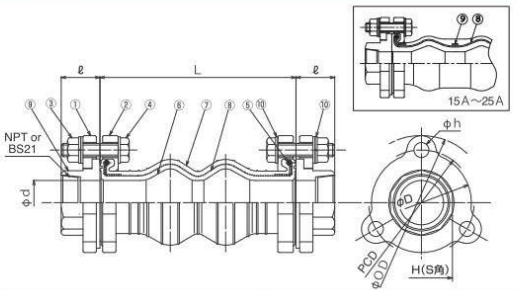

Feature

- High Efficiency for Vibration and Noise Isolation

The twin sphere makes the spring constant small, decreases the body natural frequency and increases the

efficiency of vibration absorption.

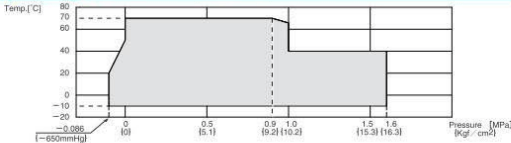

- Withstandability

It can withstand a bursting pressure of over 5.0MPa and a maximum working pressure of 1.6MPa and with

the combination of excellent formative technique and strong chemical fibre.

- Large Displacement Absorption for Eccentricity, Axial Movement and Angular Movement

Since it can absorb large displacement, TWINFLEX screwed type flexible rubber joint is most appropriate

for the protection of pipe line system. For example, it can prevent the destruction of connecting pipe

due to earthquake and subsidence of ground.

Download

For a comprehensive overview of the product specifications mentioned above, feel free to download the product

catalog here.