Excellent performance for vibration absorption,

Excellent performance for vibration absorption,

displacement absorption and

high-pressure resistance.

Multifunctional double sphere

Application

Vibration absorption for pumps and equipment, absorption of piping eccentricity, expansion and compression, and absorption of stress caused by earthquake

Installation

Air conditioning piping

Specifications

| Nominal diameter: | 20A – 300A |

| Maximum working pressure: | 1.0MPa{10.2kgf/cm²} |

| Operating temperature: | -10°C – 70°C |

| Expansion and compression eccentricity: | 15 – 30mm |

| Feature |

| Achievements Having been used in more than 20 countries for over 30 years, TOZEN brand products proudly demonstrate their popularity. Reliability Unparalleled durability is guaranteed by the distinctive and strict design standards of TOZEN. Quality Manufactured in TOZEN’s own factory under thorough control with ISO9001 quality management system. |

| Applications |

| ● This product is mainly applicable for piping systems in commercial and industrial buildings and plants. ● Applicable fluids are exclusively water including cold water, warm water, cooled water, sea water, etc. ● This product can not be used for drinking water, pool water, oil, or boiled water. |

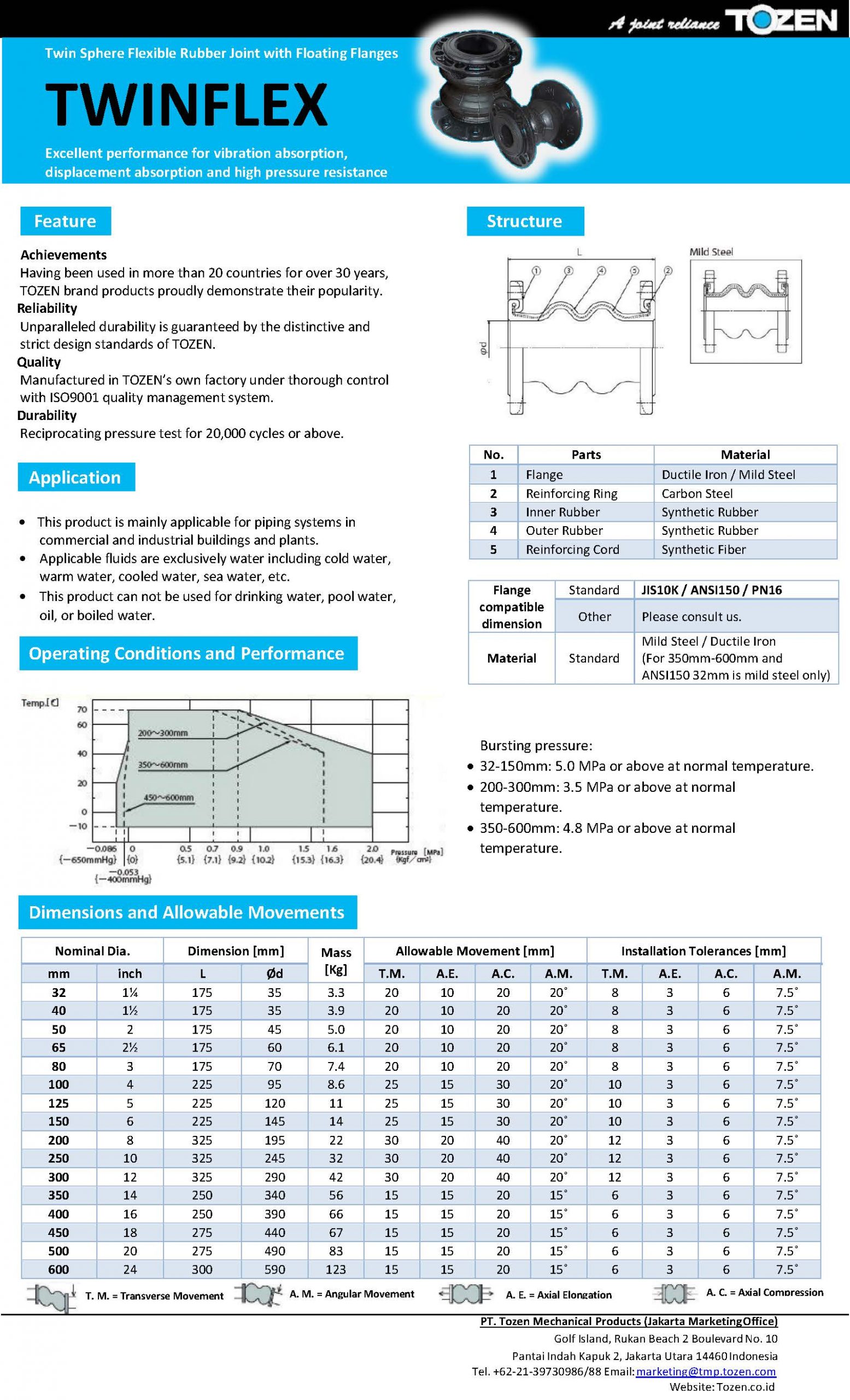

| Operating Conditions and Performance |

● Bursting Pressure ● Bursting Pressure32~150mm:5.0MPa or above at normal temp. 200~300mm:3.5MPa or above at normal temp. 350&400mm:4.0MPa or above at normal temp. |

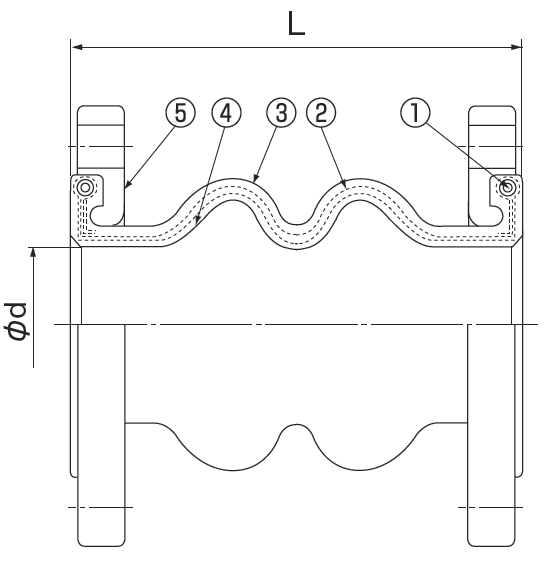

| Structure | |||||||||||||||||||||

|

|

|||||||||||||||||||||

| ● Flanges with mild steel and ductile iron in JIS10K, ANSI150, PN16 are standard. For other flanges, please consult us. ● Flange material can be changed to SUS304 and SUS316. ● Flange material for 350&400mm is mild steel only. |

|||||||||||||||||||||

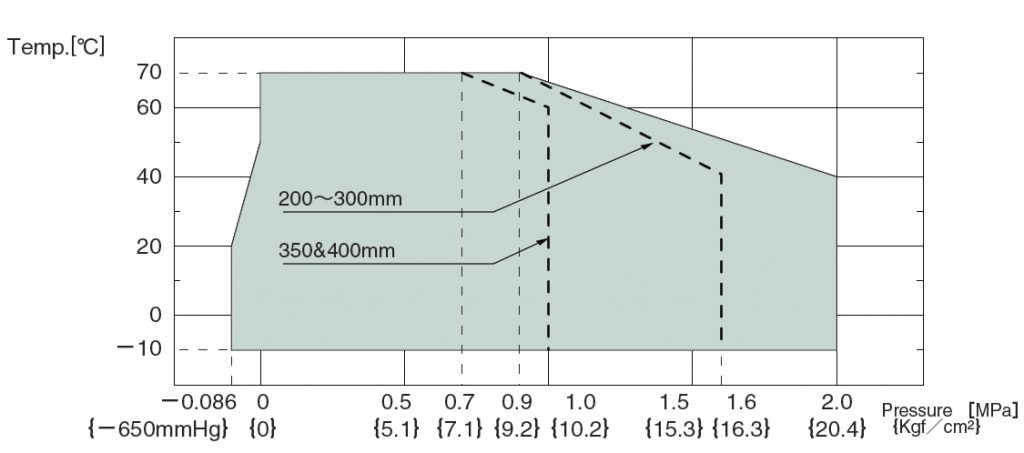

| Dimensions and Allowable Movements | ||||||||||||

| Nominal Dia. | Dimension [mm] | Mass [Kg] |

Allowable Movement [mm] | Installation Tolerances [mm] | ||||||||

| mm | inch | L | φd | T.M | A.E | A.C. | A.M. | T.M | A.E | A.C. | A.M. | |

| 32 | 1 1/4 | 175 | 40 | 2.2 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5° |

| 40 | 1 1/2 | 175 | 40 | 2.3 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5° |

| 50 | 2 | 175 | 50 | 3.0 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5° |

| 65 | 2 1/2 | 175 | 65 | 3.9 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5° |

| 80 | 3 | 175 | 75 | 4.1 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5° |

| 100 | 4 | 225 | 100 | 5.3 | 25 | 15 | 30 | 20° | 10 | 3 | 6 | 7.5° |

| 125 | 5 | 225 | 125 | 7.6 | 25 | 15 | 30 | 20° | 10 | 3 | 6 | 7.5° |

| 150 | 6 | 225 | 150 | 11 | 25 | 15 | 30 | 20° | 10 | 3 | 6 | 7.5° |

| 200 | 8 | 325 | 200 | 17 | 30 | 20 | 40 | 20° | 12 | 3 | 6 | 7.5° |

| 250 | 10 | 325 | 250 | 24 | 30 | 20 | 40 | 20° | 12 | 3 | 6 | 7.5° |

| 300 | 12 | 325 | 300 | 28 | 30 | 20 | 40 | 20° | 12 | 3 | 6 | 7.5° |

| 350 | 14 | 250 | 340 | 35 | 15 | 15 | 20 | 15° | 6 | 3 | 6 | 7.5° |

| 400 | 16 | 250 | 390 | 48 | 15 | 15 | 20 | 15° | 6 | 3 | 6 | 7.5° |

| 450 | 18 | 275 | 440 | 67 | 15 | 15 | 20 | 15° | 6 | 3 | 6 | 7.5° |

| 500 | 20 | 275 | 490 | 83 | 15 | 15 | 20 | 15° | 6 | 3 | 6 | 7.5° |

| 600 | 24 | 300 | 590 | 123 | 15 | 15 | 20 | 15° | 6 | 3 | 6 | 7.5° |

| ※Assembly with ANSI150 flange.

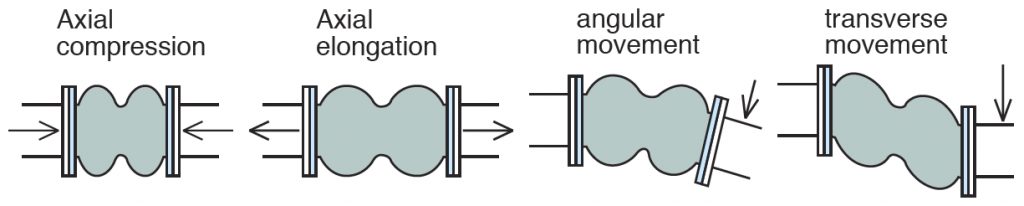

・A.C.: Axial Compression, A.E.: Axial Elongation, A.M.: Angular Movement, T.M.: Transverse Movement

|

|

|

Note:The contents of this catalogue are subject to change without notice.