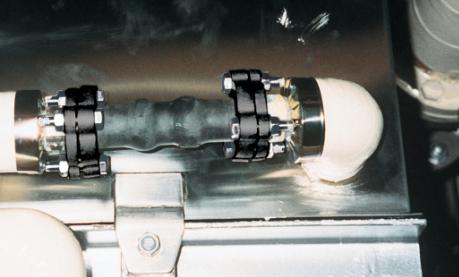

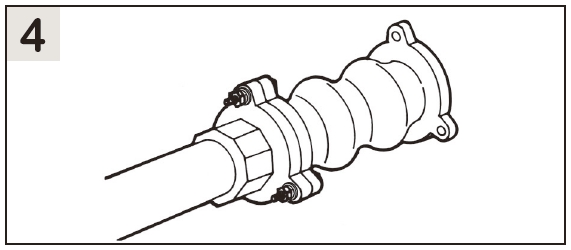

TWINFLEX Screwed Type Rubber Joint can afford large defletion that you can hardly imagine.

TWINFLEX Screwed Type Rubber Joint can afford large defletion that you can hardly imagine.

It has various functions and are highly reliable.

This double sphere TWINFLEX rubber joint allows increased compression, elongation and angular movement. The unique double sphere design improves noise and vibration isolation and dampens hydraulic surge and shock. Refer to the Product Data Sheets for more information.

Key Benefits

• Compensate for Axial and lateral movement due to thermal changes.

• Isolate noise and vibration from piping system.

• Complete union assembly provided for ease of installation.

• No gasket needed for sealing area.

Typical Application

• TWINFLEX union type joints are used for connecting pipes and equipment where threaded union ends are preferred.

| Operating Conditions | |

| Size Range | 1/2″ to 2″ |

| Max. Pressure* | 142 psig |

| Operating Temperature | 14°F to 158°F |

| Vacuum Rating* | 25″Hg |

| Burst Pressure* | Greater than 780 psig |

* at normal temperature of 80°F

| Feature |

| High Efficiency for Vibration and Noise Isolation The twin sphere makes the spring constant small, decreases the body natural frequency and increases the efficiency of vibration absorption. Withstandability It can withstand a bursting pressure of over 780 psi. Rubber body with maximum working pressure of 250 psi and with the combination of excellent formative technique and strong chemical fibre. Large Displacement Absorption for Eccentricity, Axial Movement and Angular Movement Since it can absorb large displacement, TWINFLEX screwed type flexible rubber joint is most appropriate for the protection of pipe line system. For example, it can prevent the destruction of connecting pipe due to arthquake and subsidence of ground. Applicable for both Suction and Delivery The joint fits for both suction and delivery. Highly Reliable The packing parts are strengthened with steel reinforcing rings to prevent the rubber body from slipping out of the fitting sides of flanges. Convenient to install When limited space is allowed for installation, the free type sockets can be screwed separately to pipe before fitting in the joint. |

| Applications |

| ● This product is mainly applicable for piping systems in commercial and industrial buildings and plants. ● Applicable fluids are exclusively water including cold water, warm water, cooled water, sea water, etc. |

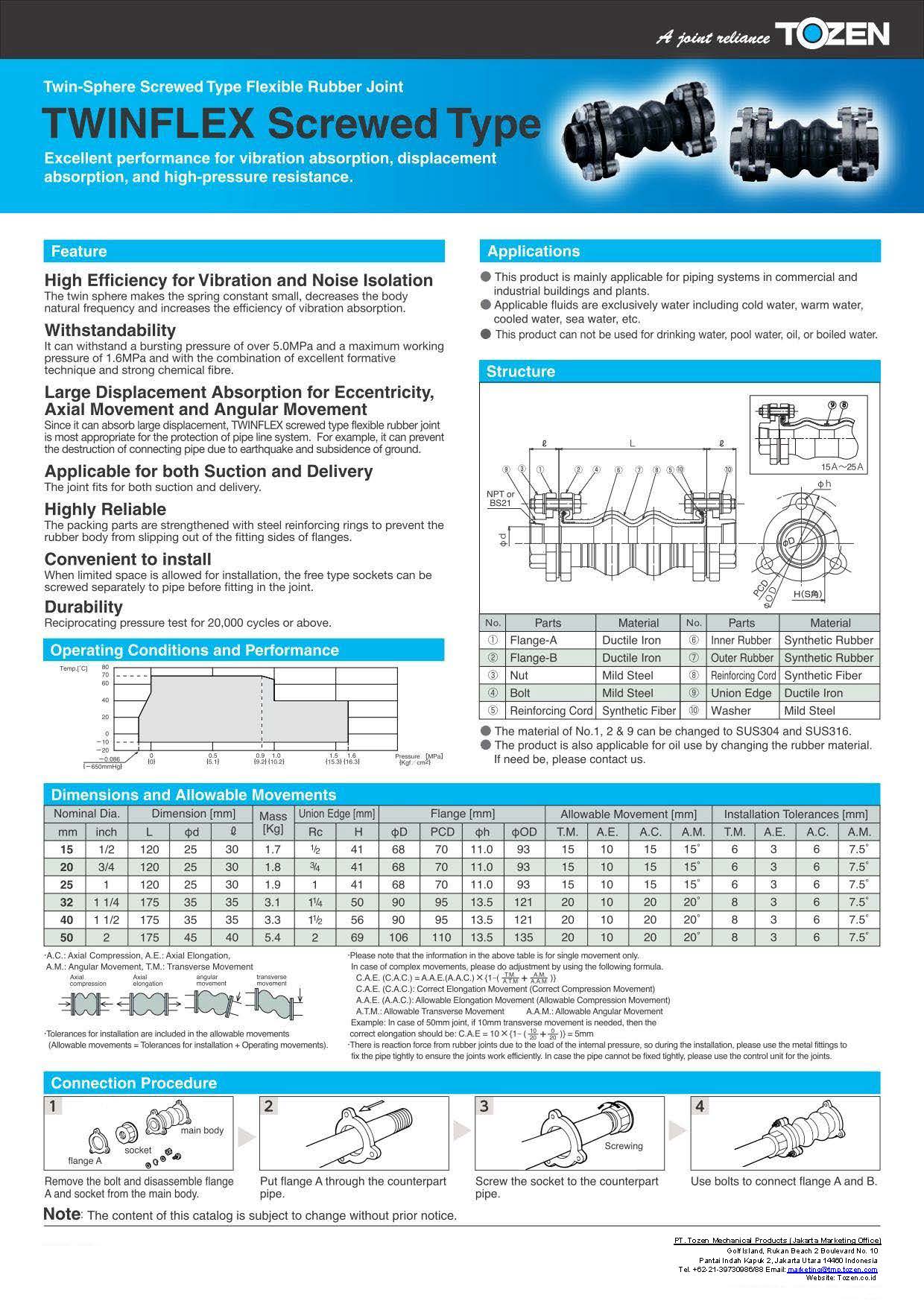

| Operating Conditions and Performance |

● Check if maximum pressure and temperature are within the range of use. |

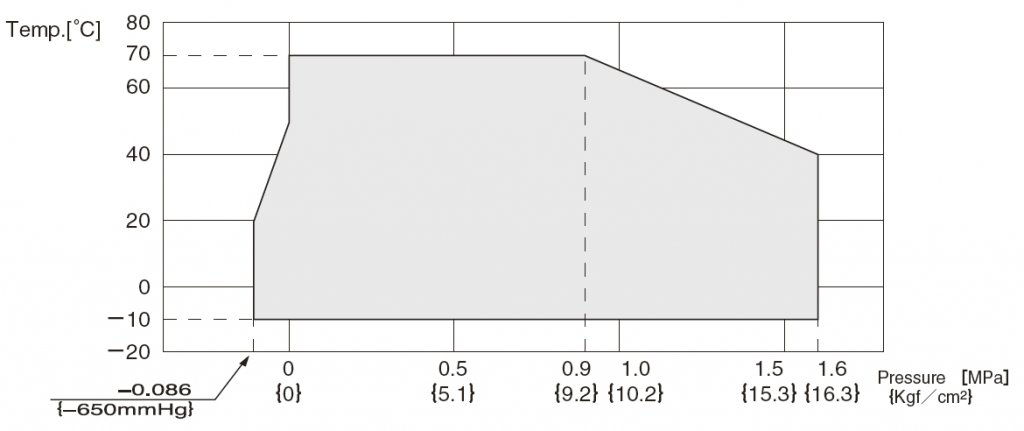

| Structure |

|

||||||||||||||||||||||||||||||||||||

| ● The material of No.1,2 and 6 can be changeable to SUS304. ● If you would like to use our products for oil application,we can supply such products by changing rubber material.Please contact us. |

| Dimensions and Allowable Movements | ||||||||||||

| Nominal Dia. | Dimension [mm] | Allowable Movement [mm] | Installation Tolerances [mm] | |||||||||

| mm | inch | L | φd | ℓ | T.M | A.E | A.C. | A.M. | T.M | A.E | A.C. | A.M. |

| 15 | 1/2 | 120 | 25 | 30 | 15 | 10 | 15 | 15° | 6 | 3 | 6 | 7.5° |

| 20 | 3/4 | 120 | 25 | 30 | 15 | 10 | 15 | 15° | 6 | 3 | 6 | 7.5° |

| 25 | 1 | 120 | 25 | 30 | 15 | 10 | 15 | 15° | 6 | 3 | 6 | 7.5° |

| 32 | 1 1/4 | 175 | 35 | 35 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5° |

| 40 | 1 1/2 | 175 | 35 | 35 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5° |

| 50 | 2 | 175 | 45 | 40 | 20 | 10 | 20 | 20° | 8 | 3 | 6 | 7.5° |

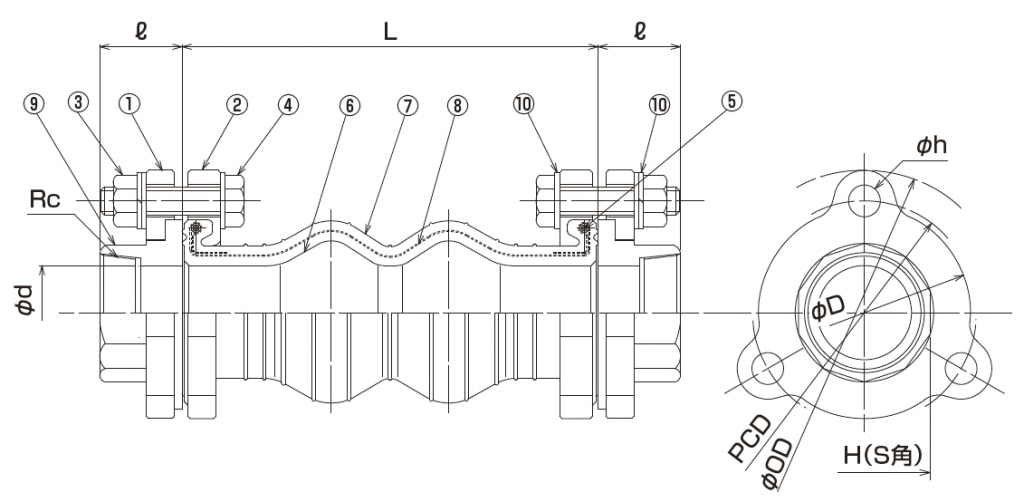

● T.M=Transverse Movement

● A.E=Axial Elongation

● A.C=Axial Compression

● A.M=Angular Movement

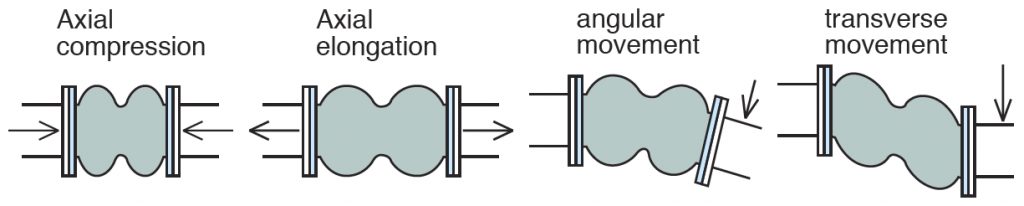

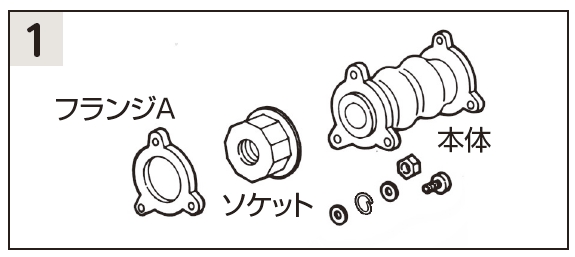

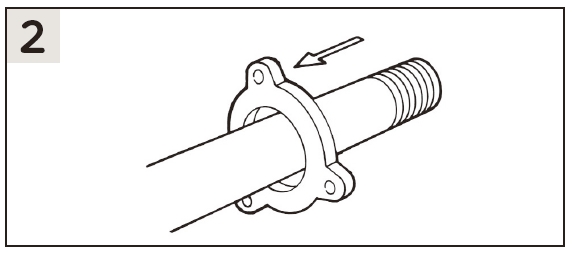

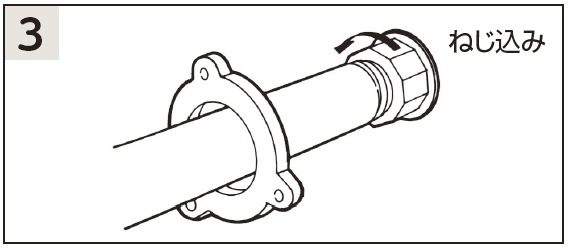

| Connection Procedure |

|

|

|

| Remove the bolt and disassemble flange A and socket from the main body. | Put flange A through the counterpart pipe. |

|

|

| Screw the socket to the counterpart pipe. | Use bolts to connect flange A and B. |

Note:The contents of this catalogue are subject to change without notice.