|

|

ApplicationTOZEN PTH-G vibration-isolating hangers are used to isolate suspended sources of audible frequency vibration, or isolation of noise in piping and ductwork systems. Model PTH-G hangers are shipped fully assembled and ready for installation in threaded rod suspended systems. Model PTH-G hangers can be provided with labor saving accessories for adaptation to wire or strap suspension systems.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTH-G

Specification

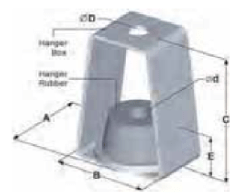

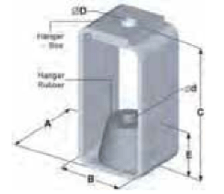

Vibration isolators for suspended equipment, piping and ductwork with maximum static deflection requirements under operation load conditions not exceeding 6 mm shall be hangers consisting of a neoprene or synthetic rubber noise absorbing insert encased in a welded steel box. The rubber insert shall be moulded from oil resistant compounds with cast in load transfer plate at the top and bottom, shall be color-coded or otherwise identified to indicate load capacity. Vibration isolating rubber hanger assembly shall be Model PTH-G, as manufactured by Tozen Sangyo Co., Ltd.

Download

For a comprehensive overview of the product specifications mentioned above, feel free to download the product catalog here.

Description

TOZEN PTH-G vibration isolating rubber hangers are designed to reduce the transmission of vibration and noise produced by suspended equipment, piping and ductwork. PTH-G hangers incorporated with a noise absorbing rubber insert with cast-in load transfer plate at the top and bottom, assembled into a steel box. Ultimate design of PTH-G hanger rubbers allows greater deflection without accelerating deterioration. PTH-G hangers are available in deflection maximum up to 6 mm with capacities from 25 Kgs to 450 Kgs. PTH-G rubber hangers may be selected where first cost must be minimized. MODEL PTH-G is recommended for the isolation of vibration produced by suspended mechanical equipment, axial and exhausts fans, ductwork, piping, etc. Double deflection model PTH-GG adds another rubber element at the top of the hanger box.